Same Day

Shipping for

Online Orders

Before 1pm

30 day

Money Back

Guarantee

Background

A cold chain is a low temperature-controlled supply chain network that ensures the food, beverages, medication, and volatile chemicals are still safe to use after they reach the consumers. To do this right, the temperature is a profoundly vital factor. Bacteria grows quickly and could taint consumable goods if the transporters do not keep them at the right temperature. Cold rooms, warehouses, order assembly points and loading docks all have specific temperature profiles that must be monitored and maintained based on the products being stored or transported. The Milesight cold chain monitoring solution offers a reliable and accurate solution, with the PT100 temperate sensor being one of the best ways to ensure the efficacy and safety of temperature-sensitive products.

Why PT100

The PT100 temperature sensor is an instrument that converts temperature variables into a standardised output signal that can be transmitted. They have been used for many years to measure temperature in the cold chain, laboratory and industrial processes, and have developed a reputation for accuracy, repeatability, and stability.

Challenges

Control at Specific Level

Cold chain Logistics service providers need to offer a controlled environment, refrigerated, frozen, deep freeze and cryogenic freezing services, which can be complex as each has its own temperature requirements and application.

Maintenance in Transit

Shipments pass through a variety of environments and handlers. Considering any deviations in temperature could affect the safety of products, it’s difficult to manage complicated cold chain effectively without real-time information.

Solution

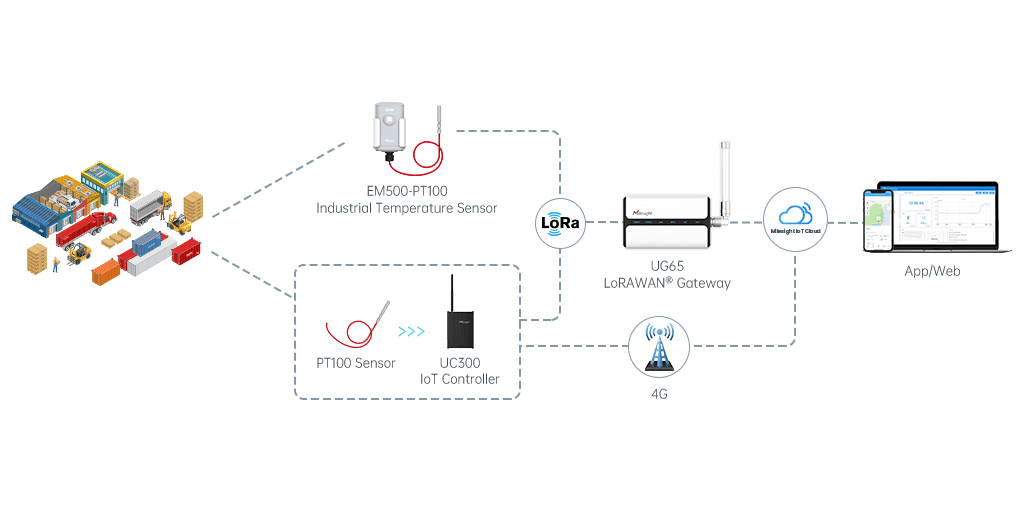

An industrial temperature monitoring system for cold chain can be useful on any type of equipment with moving parts and components. Milesight offers two workable solutions tailored to customers’ needs. For new LoRaWAN solution deployment, the EM500-PT100 Industrial Temperature Sensor would be a good candidate. It is a three-wire RTD design and performs perfectly as cold as -200 °C (-328 °F). By transporting data from the EM500-PT100 to the UG65 gateways, real-time monitoring and alerts of temperature on the Cloud platform are achievable easily.

For upgrades to existing deployments, the UC300 IoT Controller could be a better fit. With 4~20 mA and 0~10 V type analog interfaces, the UC300 adopts 2 RTD inputs for accepting and converting the resistance signal of 2/3 wires PT100 sensors into 4-20 mA current signal with a range from -200°C to 800°C. The UC300 IoT Controller supports 4G and LTE, so the deployment of technology is more flexible.

The Milesight cold chain monitoring solution topology

Featured Product

- EM500-PT100 Industrial Temperature Sensor

- UC300 IoT Controller

- UG65 Semi-industrial LoRaWAN Gateway

- Milesight IoT Cloud

Benefits

- Quality Assurance

Mapping the temperature of storage facilities can offer solid information to manage product quality. By setting suitable reporting intervals, users can be informed timely with accurate data.

- Simplified Management

With straightforward data directly shown on the cloud platform, companies in the cold chain network could have a holistic understanding of quality control performance overall.

- Prevent Unplanned Downtime

With temperature data and real-time alerts, maintenance technicians gain the flexibility to address a problem at a more convenient time while preventing equipment failure.

Powertec provides full network design

services.

Contact our team to begin your automation journey today on 099516205 or solutions@powertec.com.au