Same Day

Shipping for

Online Orders

Before 1pm

30 day

Money Back

Guarantee

Critical Communication – Wi-Fi Underground Communications System

Business Profile

Managing business requirements alongside safety for staff who work underground can be a sensitive balancing act, and one that you can’t afford to fail.

These issues did not support robust health and safety outcomes, they placed limits on the amount of tunnel investigation work done underground in a single session, and did not allow widespread communication when issues forced further consultation with other company staff.

Powertec suggested that Wi-Fi be tested and worked with the partner client to arrive at the solution. Wi-Fi initially had its own challenges – it had to operate above and below ground, the best frequency had to be determined and it needed to be reliable over some very adverse terrain.

One issue imperative to address was how to create a closed loop IP Network to allow handover from end to end.

Because of this it is important to take advantage of improvements in technical and new product development aimed at reducing business costs, upgrading business information and improving staff safety.

The Wi-Fi Underground Communication System (UCS) was developed by Powertec Telecommunications in conjunction with our resellers for a specific client to improve their current method of communication when staff were traversing underground tunnels.

The final result produced great outcomes for the client – less staff required to do the task, better communication and improved safety. The Altai Super WiFi Underground Communication System was tested head to head with an alternative popular competitor and beat them across the board in terms of ease of operation, coverage and signal strength.

Overview

The client brief was to update communications when traversing through the network of underground tunnels by replacing the UHF push to talk/2way radio system used to communicate between the surface and the traverse teams. The UHF system was used primarily for voice communications and was unreliable, with fairly sketchy service on occasion and only operated in shortWi-Fi Underground range.

Products

The UCS was pre-configured and provided as a boxed solution in a high impact Pelican suitcase. Altai Super WiFi products were used due to their high quality carrier grade and proven performance to increase capacity and extend coverage.

- Altai A2

The Altai A2 is a powerful access point/bridge solution with an integrated 5GHz backhaul radio and antenna, designed for micro WiFi coverage and high throughput PTP/PTMP bridging. The A2 includes a MIMO 2.4GHz 801.11 b/g/n radio with a set of 2 antenna ports, and a MIMO 5GHz 802.11a/n radio with an integrated dual-slant high-gain antenna, making it a simple-to-deploy solution for remote micro coverage with integrated backhaul.

- Altai C1an / C1xan

The C1an and C1xan are high-performance WAP’s designed to increase WiFi signal strength (transmission and reception) as well as the client’s throughput. They can be configured as AP, STN, Repeater Bridge.

- Rugged HSP/LTE routers

- ICOM Handheld communication device

Proof of Concept

It was determined that using the 5ghz was the better frequency as it would tend to reflects of surfaces rather than penetrate – a benefit when working with underground tunnels that are not straight. All staff held an ICOM device that controlled the Wi-Fi push to talk system.

The test was conducted in a 1.8km stretch of tunnel with man hole access entrances at each end of the test section. The tunnel was a dogleg shape.

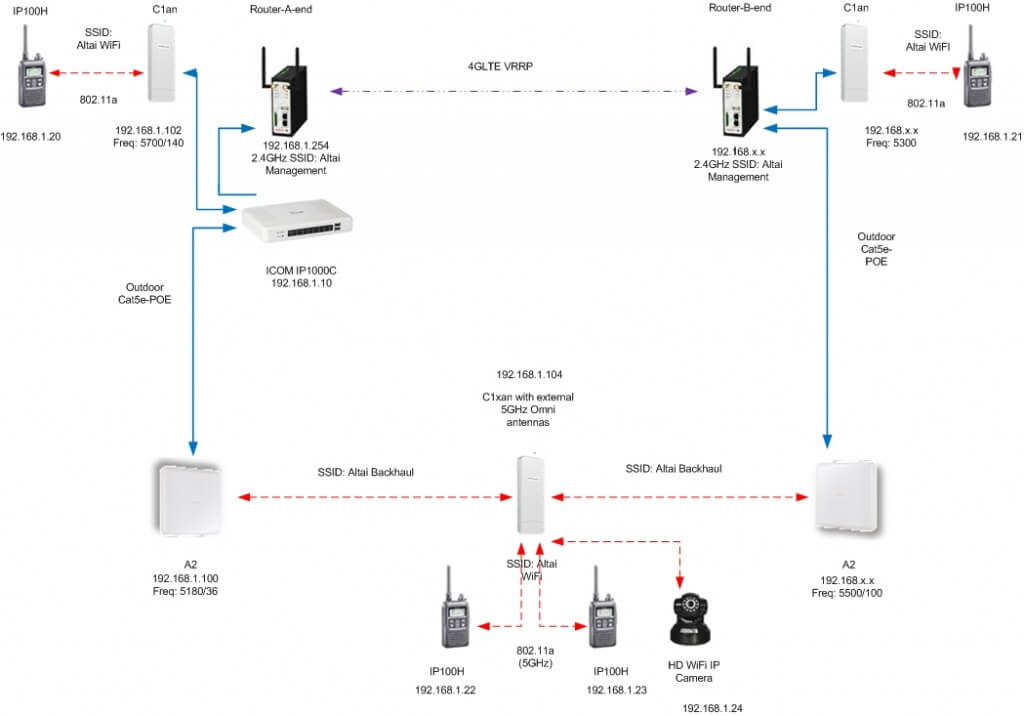

An Altai A2 was winched down on a tripod via the access entrance at each end of the tunnel, positioned to face each other. A router was positioned at the top of each access entrance along with an Altai C1an for surface access.

The positioning of the Altai products above and below the ground produced a closed loop IP network that the ICOM Wi-Fi push to talk hand phones could operate on.

Traverse staff and rescue teams already work with a backpack carrying their required items and a modified battery powered Altai C1xan with external antennas was included (adding no more than 1kg to the total weight). This acted as a repeater for the signal from the A2 that was positioned at the access point at the start of the tunnel entrance. As the team traverses the tunnel doing their investigation, the C1xan within the backpack reaches a predetermined threshold and then hands over to the next A2.

The handover threshold in this instance occurred at 1250 metres into the tunnel from the starting point.

There are a number of ways to handle the movement of the Wi-Fi IP network and this case study would potentially move the 1st UCS components and leapfrog it to the 3rd access entrance. The 2nd UCS would then be turned around to face the 3rd and staff could begin their traverse of the new section.

Wi-Fi Underground Communication System Network Diagram (case specific)

Final Outcome

A typical above and below ground traverse team could comprise of: 2 teams tunnel traverse staff each supported by a rescue team, chemists, engineers, a communications specialist, and an underground rescue specialist. It would not be uncommon for 24 people to spend the day investigating one 2km length of tunnel. If there were any issues found, that number would grow as HQ staff and additional specialists may be needed at the site for consultation.

Utilising the Wi-Fi UCS could eliminate the need for engineers, chemists, management and other staff to be onsite. The access to Wi-Fi now provides data from the underground traverse – vision, voice, video, monitoring, air quality sensors and more.

Communication can now be done with relevant management, chemists, and engineers, providing live access but no need for staff to leave their offices. Project costs would be reduced.

The traverse can now be done in a reduced time. It is possible that productivity could increase by over 200% (10km in one day instead of 2km).

Safety standards would improved for staff with access to live images and constant contact.

- Stormwater drains

- Water tanks, gas tanks, ships

- Building sites/high rise buildings

- Underwater exploration (currently proof of concept stage)

Where you have a job that can be run from a packet switch network there is no need to send maximum people to do the work. You can utilise vision and data from a UCS system to improve the access and save money.

Application

The Wi-Fi Underground Communication System should result in cost savings, increased productivity and improved staff conditions – it has applications across a myriad of industries who manage the following kit:

- Water pipe/sewerage monitoring

- Underground tunnels

- Gas pipe inspections

- Lift shafts

Request a Free Consultation

Get an expert appraisal of your connectivity needs.